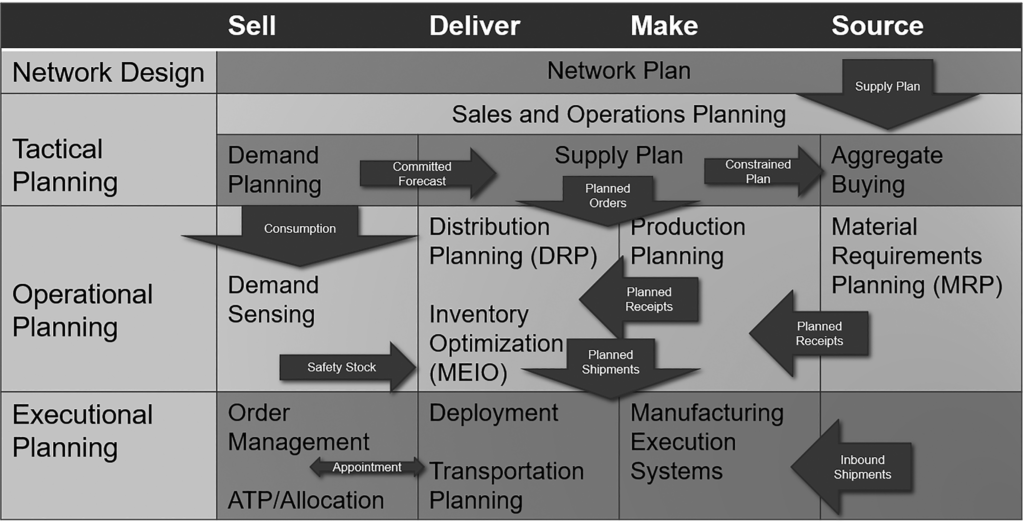

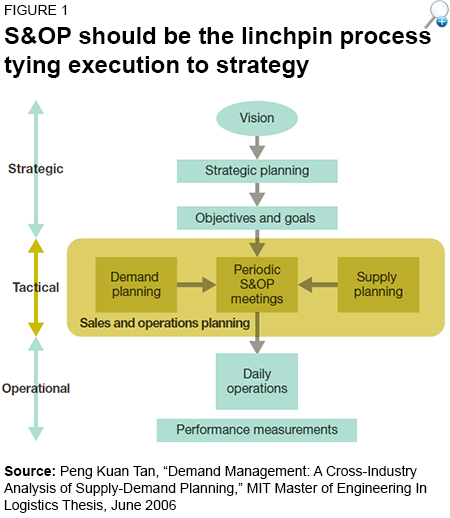

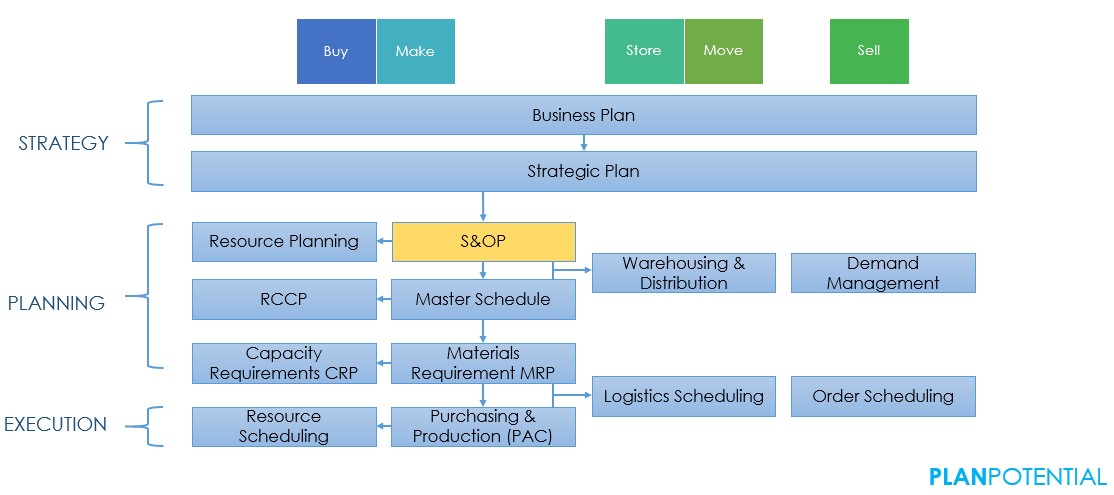

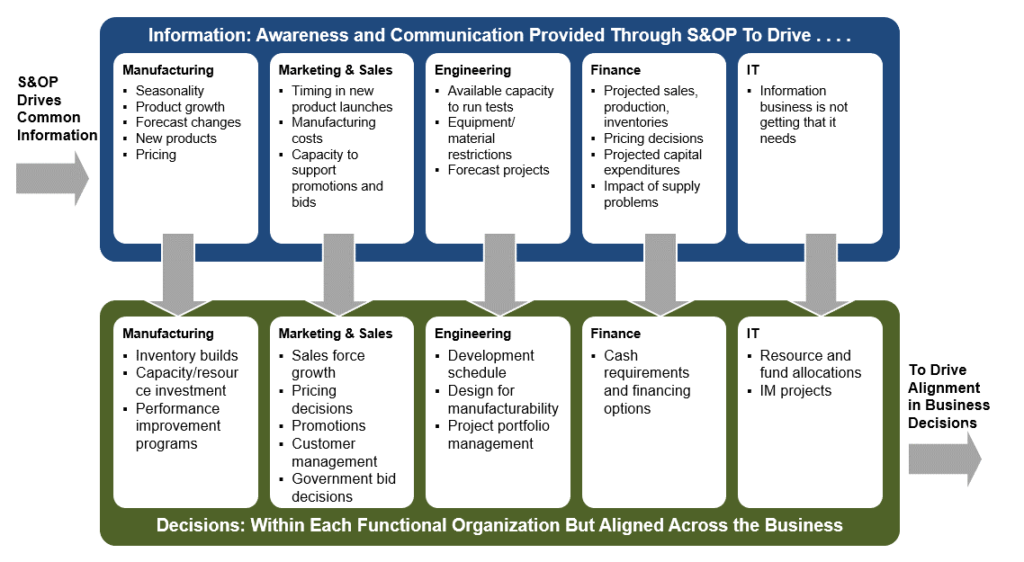

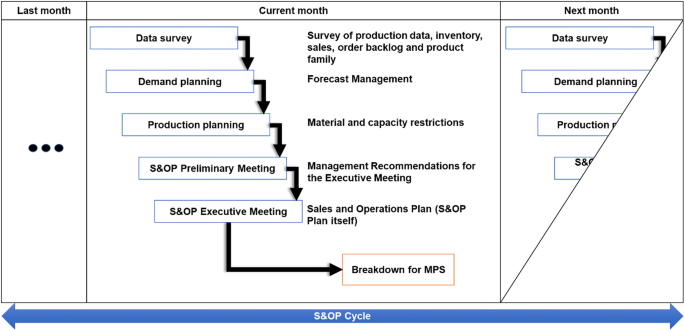

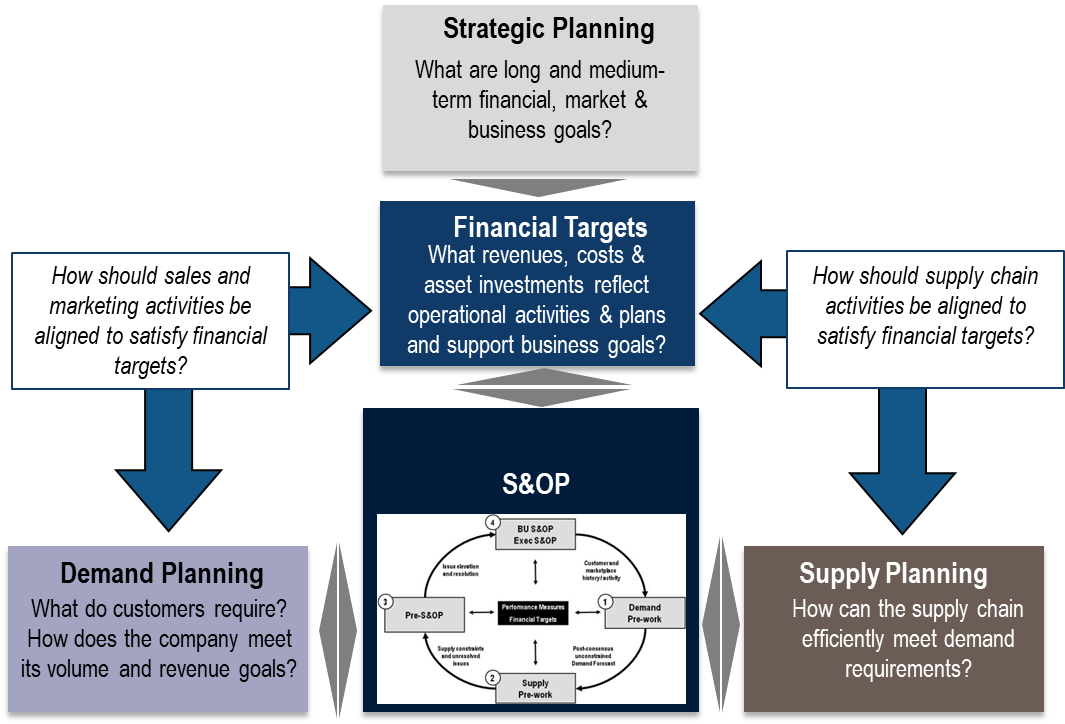

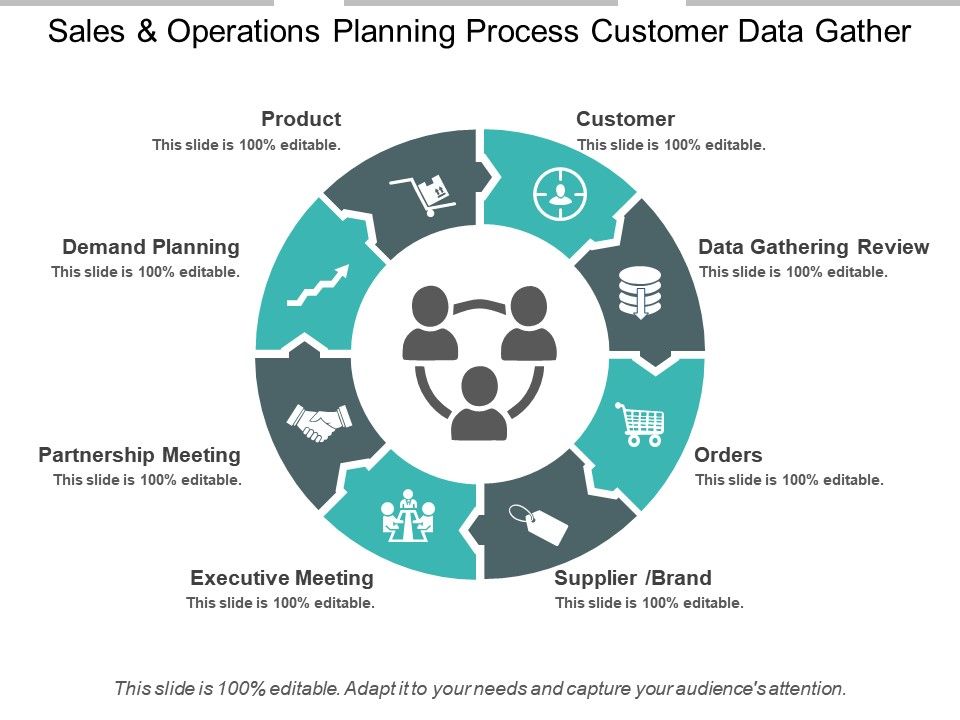

Sales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plans As a highlevel executive strategy system, S&OP starts with gathering data about variables such as sales forecasts, cash on hand, and inventory From there, a formal meeting for demand planning ensues to build forecasts without inputS&OP, or sales and operations planning, is an integrated business management process that drives organizational consensus to balance supply and demand The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so they

2

S&op demand planning meeting

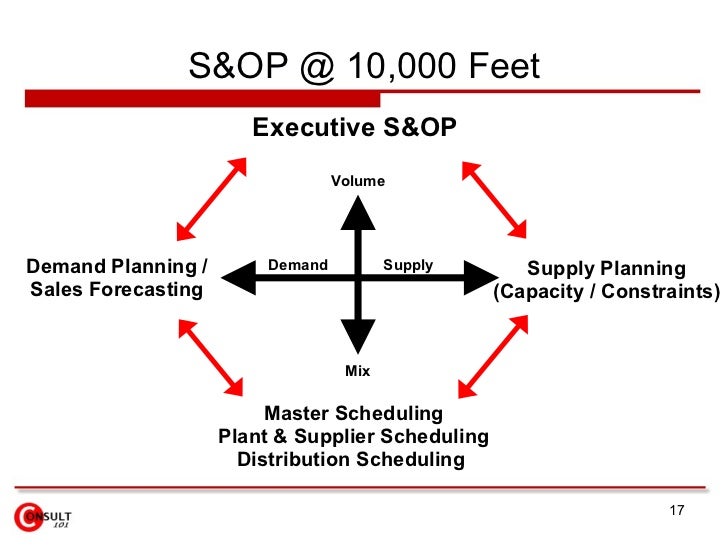

S&op demand planning meeting- S&OP Process The S&OP process includes supply and demand planning and forecasting, combined with executive oversight With the ultimate objective of coordinating sales and operations planning, a successful result aligns every department and every business process towards a common goal Generally, the steps taken in sales and operationsTake S&OP to the next level with new approaches such as dynamic inventory planning and more Reconciling Perspectives 23 Exploring the central aspects of demand alignment By Bradley McCollum Explore the strategic objectives of demand alignment and the key factors of

You Simply Need To Know What Do Next

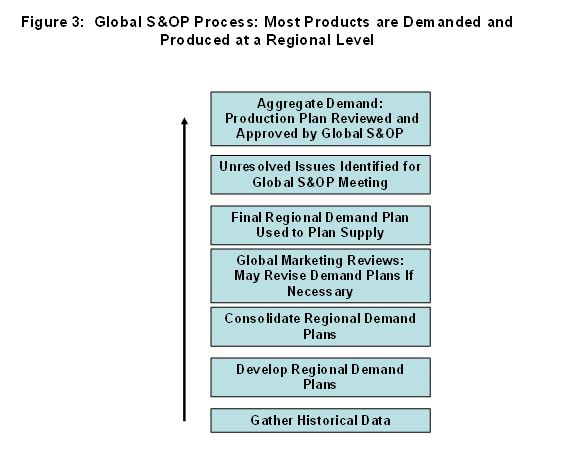

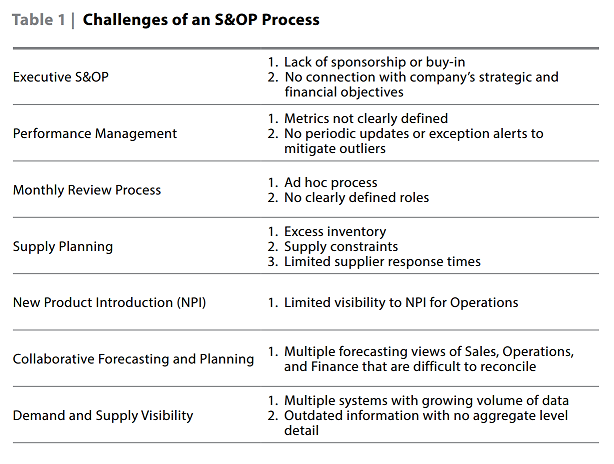

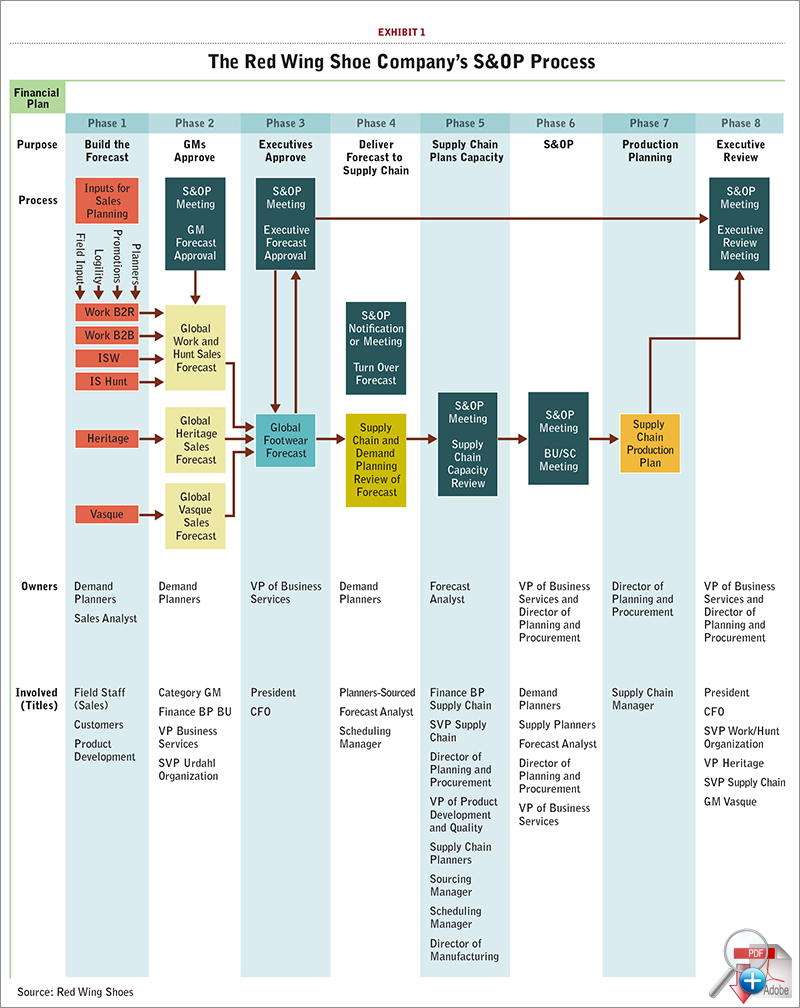

All the planning is done in the segmentlevel S&OP process, which is made up of 26 horizontal processes Some of our clients find they have some of the 26 different horizontal planning processes already in place, at least in part The 26 are shown in Figure 54;The Sales and Operations Planning (S&OP)1 process is well known and understood in the world of supply chain management In most companies, the monthly S&OP meeting brings executives from all major operational departments – sales, marketing, materials/procurement, manufacturing, transportation, and finance – together to The Institute of Business Forecasting & Planning (IBF)est 19, is a membership organization recognized worldwide for fostering the growth of Demand Planning, Forecasting, and Sales & Operations Planning (S&OP), and the careers of those in the field

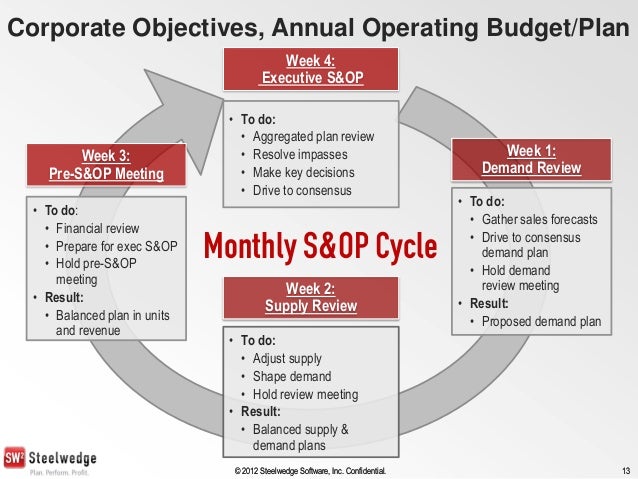

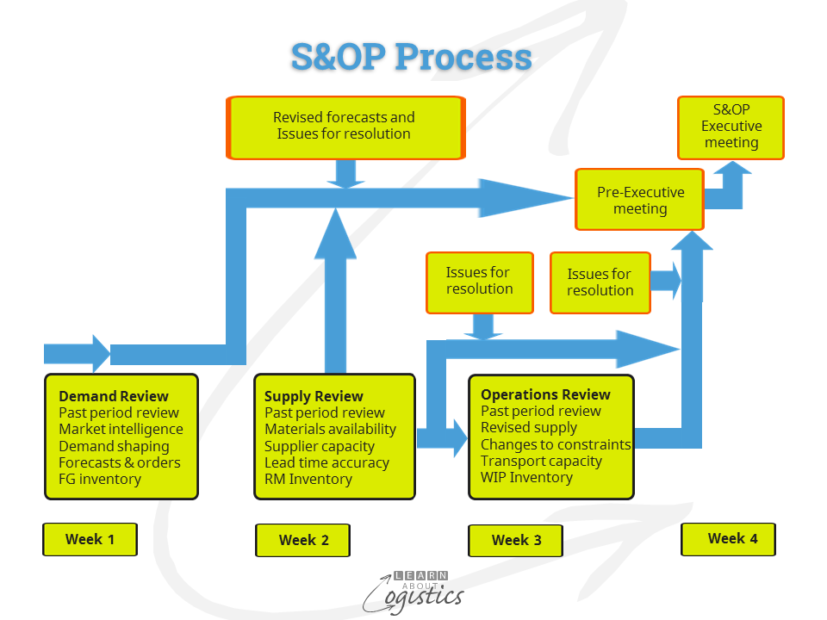

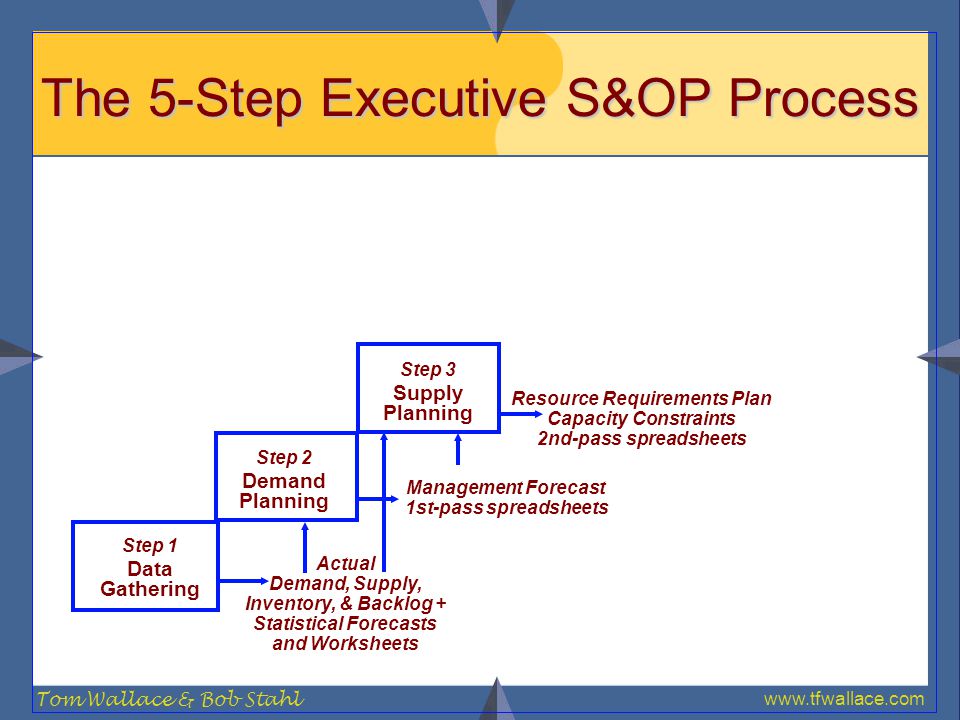

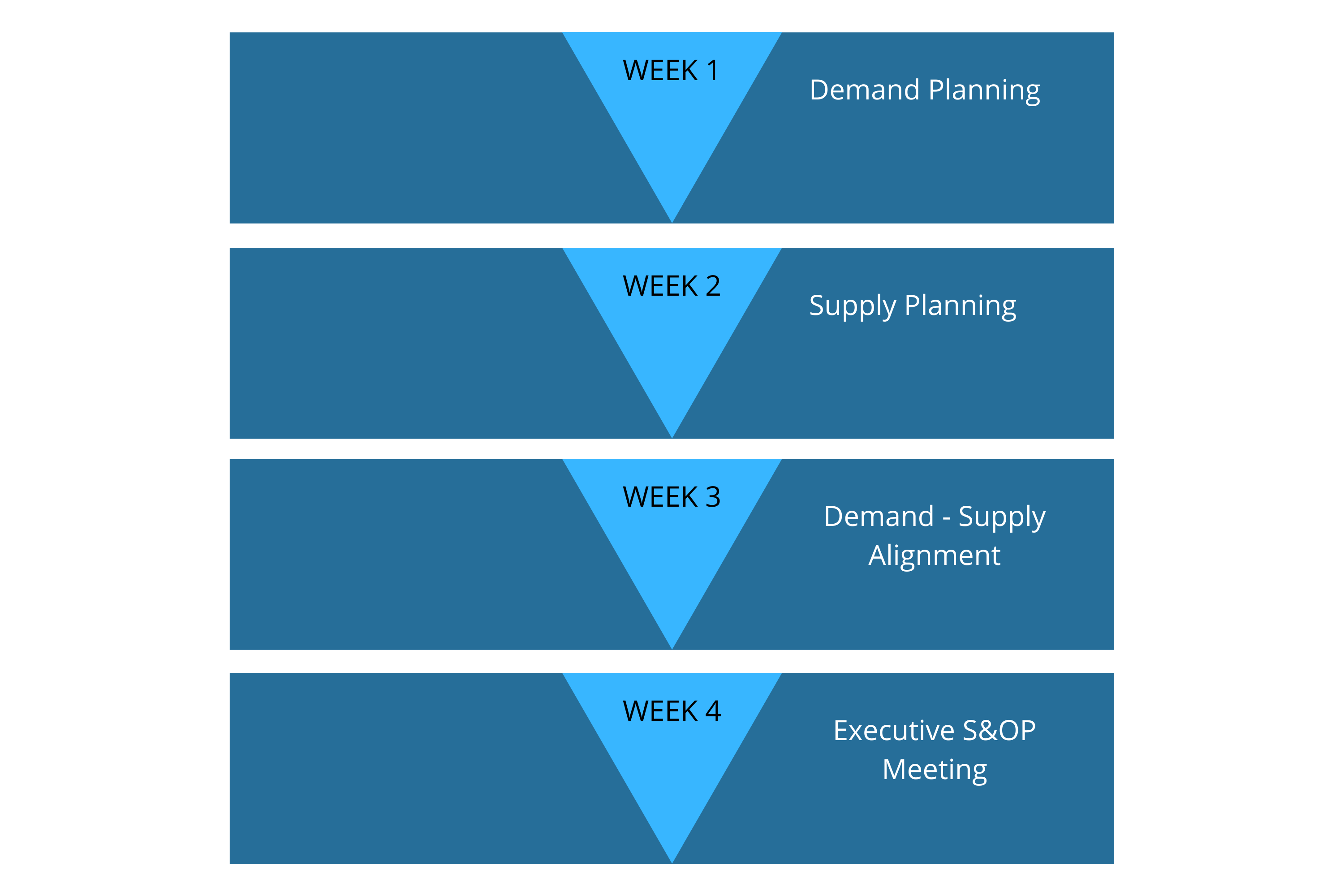

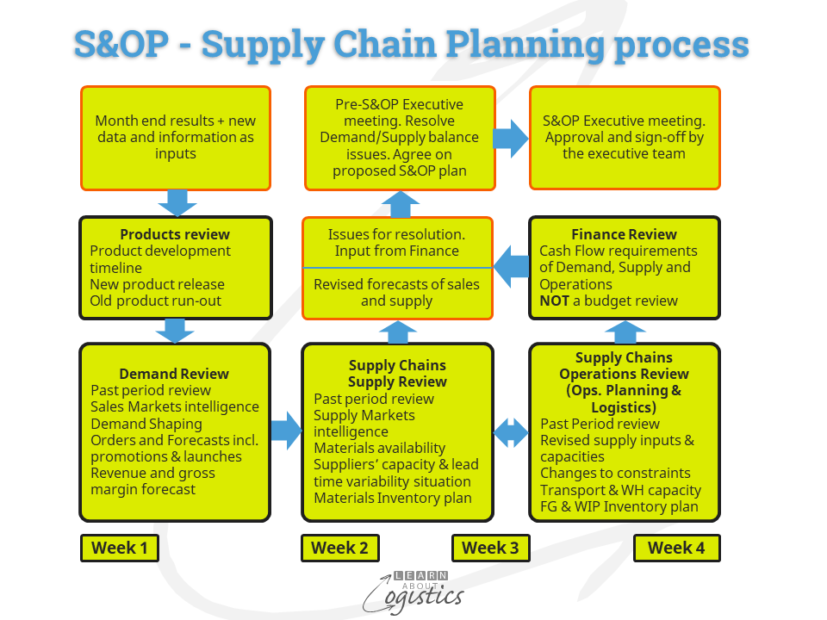

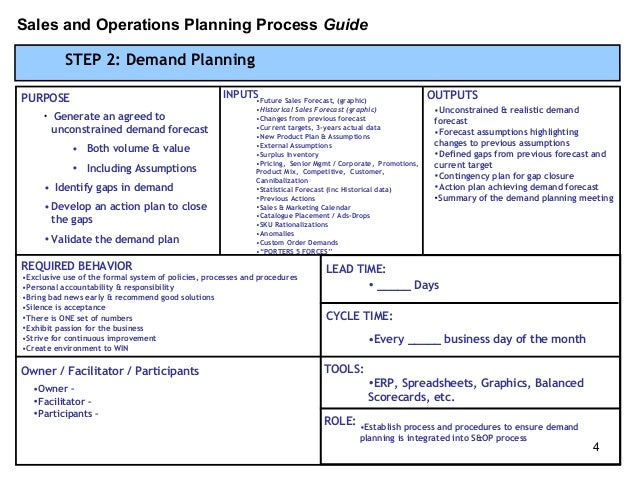

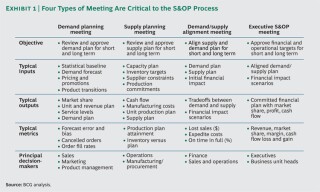

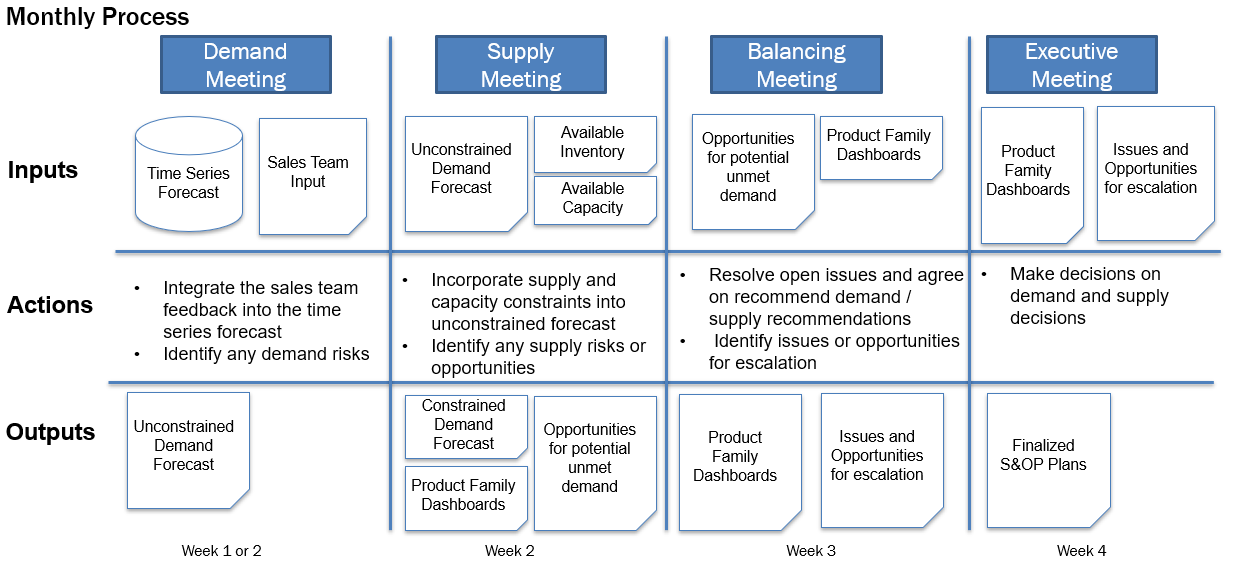

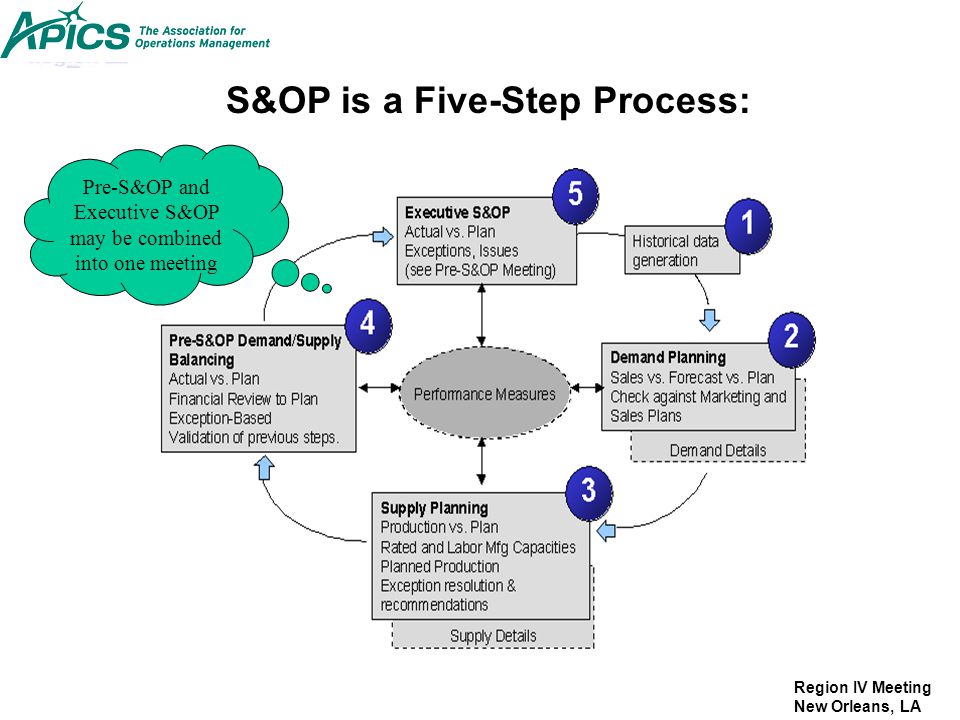

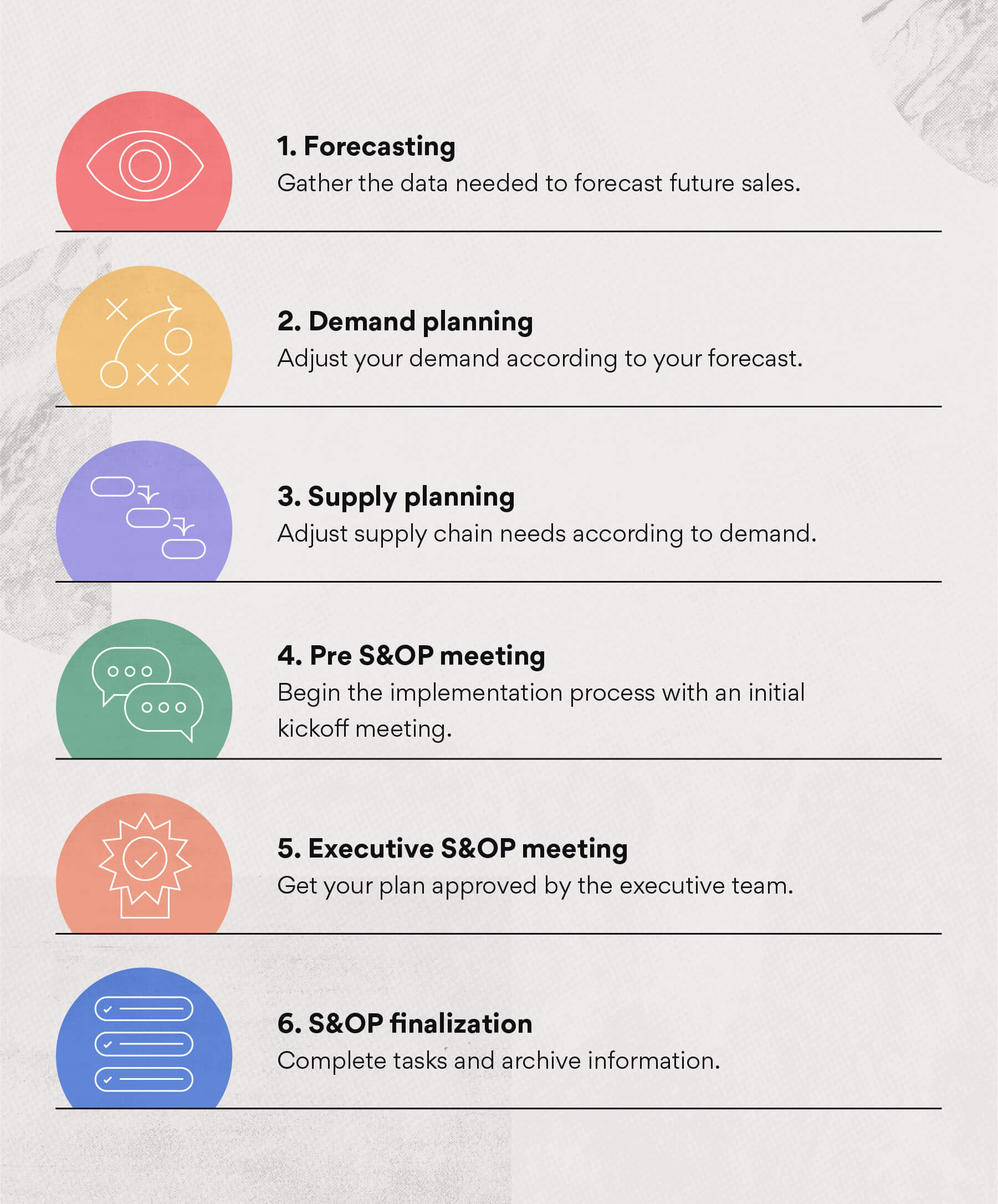

S&OP allows companies to intelligently streamline operations in order to boost profit numbers Common Steps in the S&OP Process The S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementation The Institute of Business Forecasting & Planning (IBF)est 19, is a membership organization recognized worldwide for fostering the growth of Demand Planning, Forecasting, and Sales & Operations Planning (S&OP), and the careers of those in the fieldS&OP meetings are decision meetings – not discussion meetings The ability to make decisions is the most central element in the whole process!

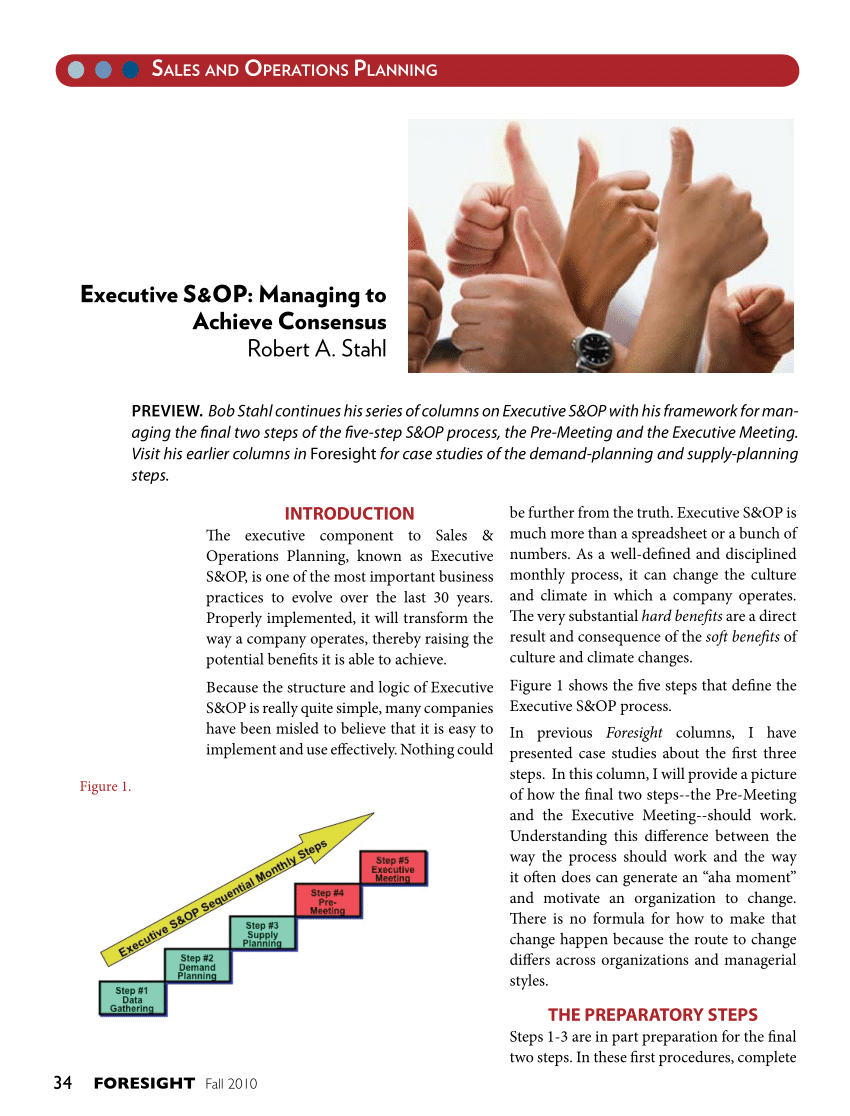

Approve or change recommendations from the pre S&OP meeting for demand and supply plans, authorize any changes to plan (new machines, hire additional labor), review key performance measuresWho?To accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 stepsS&OP process owner Demand planning team Supply planning team PreS&OP team Sets top management expectations, authorizes necessary resources, and clears obstaclesLeadership accountability answers the question Leads the monthly S&OP planning process, manages conflict, and guides the S&OP teams toward consensus

Dp Vs S Op Process Flow

Continuous Sales And Operations Planning

S&OP manager typically runs meeting Team includes VP sales, VP marketing, VP SCM, VP finance, VP operations, VP product managementSales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationThe S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new productEven though the HANA engine allows running simulations directly at the S&OP meeting, it is still recommended that focus is on decisionmaking and information rather than data

0以上 S Op Demand Planning Meeting What Is S Op Meeting Gambarsae6p5

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

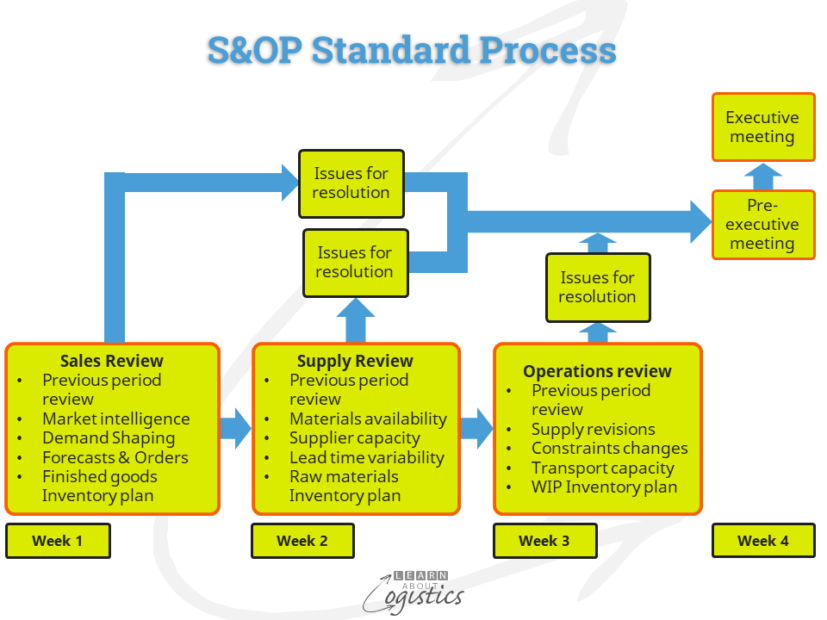

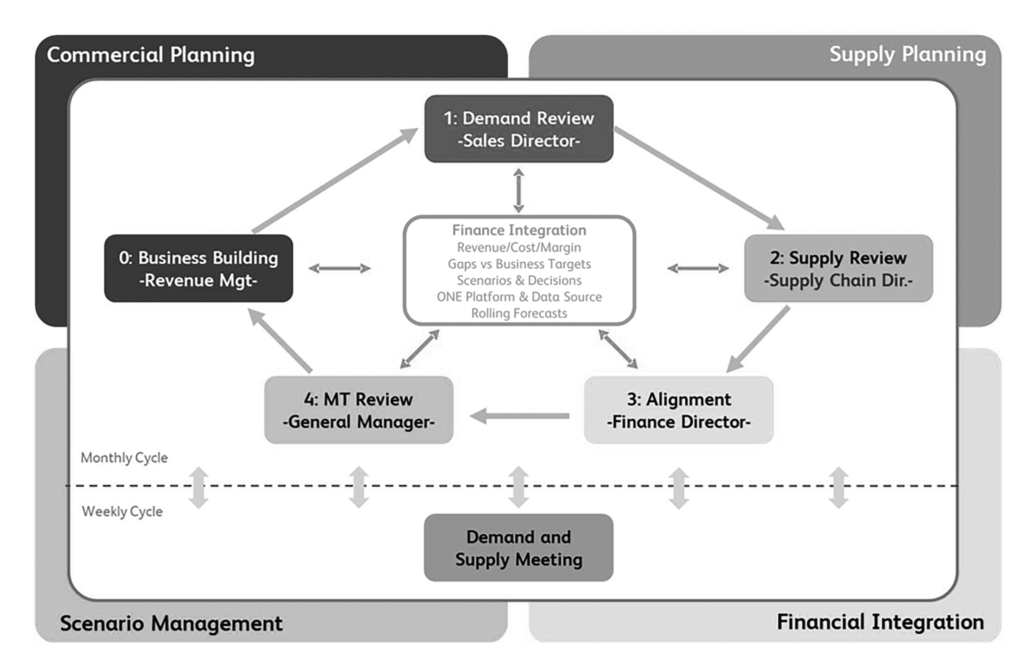

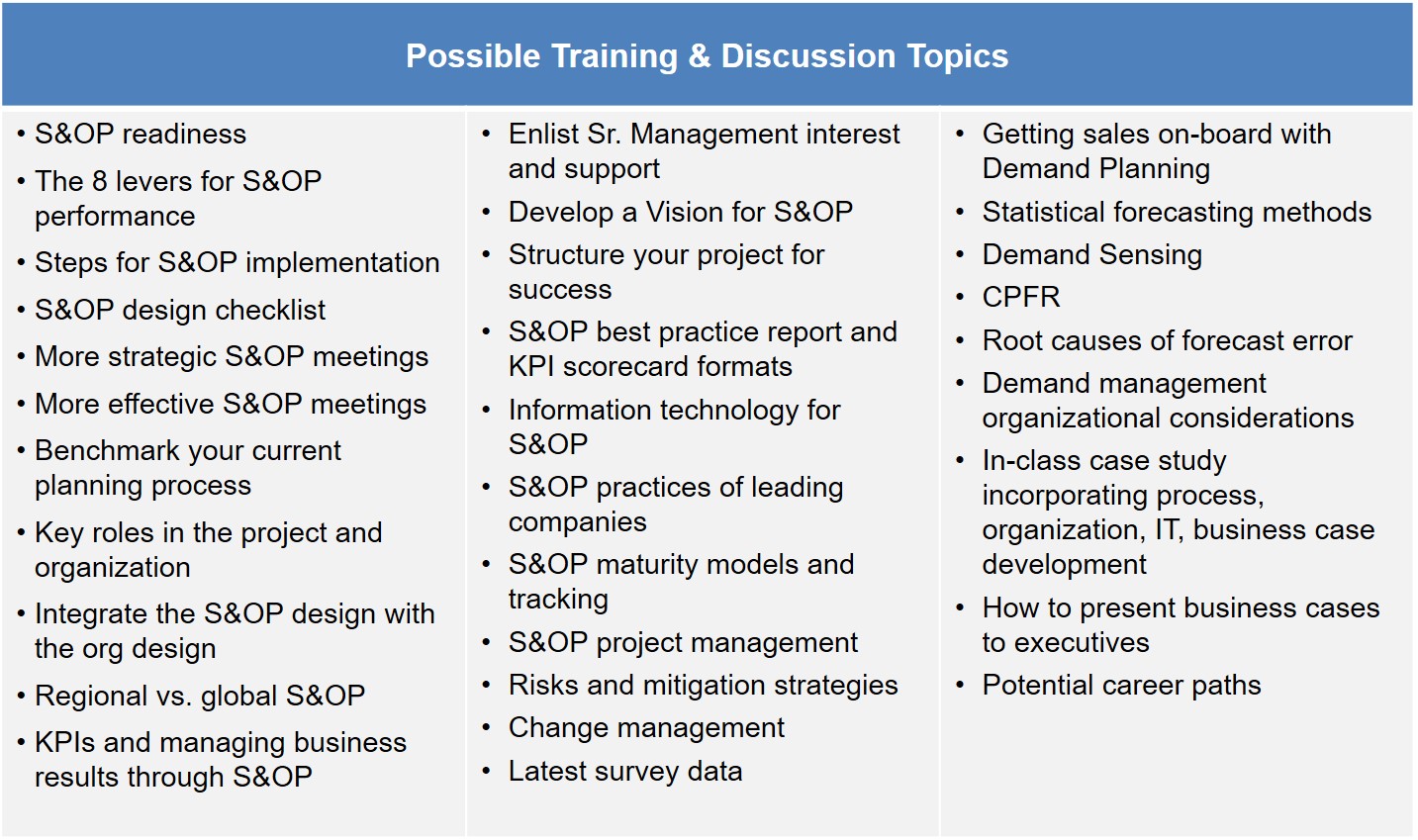

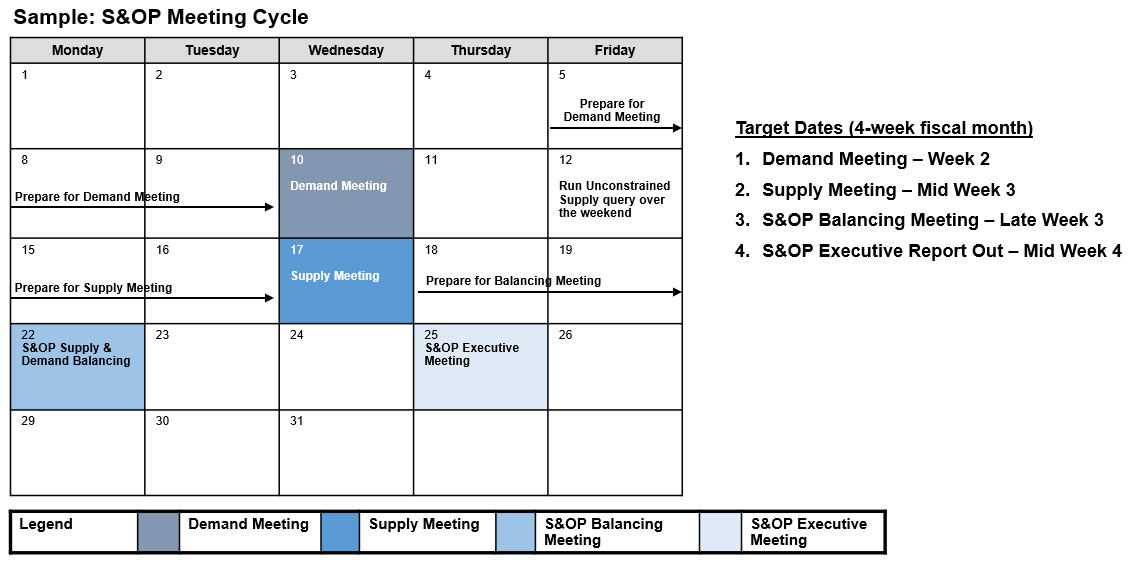

The Key steps in an S&OP process redesign Assess the key objectives of the Planning Process Identify and Involve stakeholders in Sales, Supply Planning, Operations, Marketing, and Finance during the process definition phase Interview key General Managers and understand their informational needs from the Sales and Operations Planning process1 Ongoing, Routine S&OP Meetings A key aspect of an S&OP process is that it is comprised of routine meetings that are held on a periodic basis In terms of frequency, a decade ago, Joint supply and demand planning to ensure balance 10 Measurement of the process 11 Supported by integrated supplydemand planning technology 12 External3 Part of an S&OP Process Elements of S&OP meetings • Number of meetings – One To match supply and demand – Three Demand, then supply, then final executivelevel adjustments • Frequency and length – Monthly or weekly – 2 hours to half of a day • Crossfunctional – Demand forecasting organization – Supply chain

Sales And Operations Planning Defined

Sales And Operations Planning S Op 101 Smartsheet

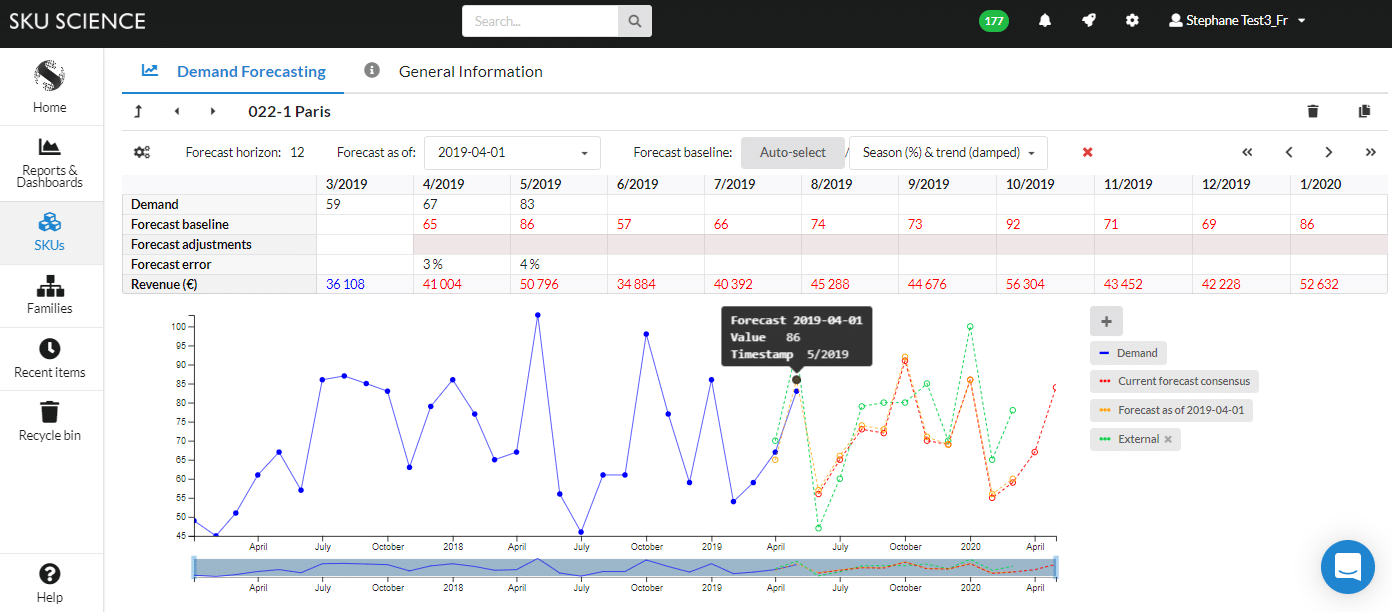

While inventory optimization and S&OP use the same demand plan, inventory optimization has typically been implemented as a standalone process In fact, many inventory optimization software packages have builtin demand planning capability This functional duplication with S&OP further attests to the practical exclusivity of the two processes•S&OP is about coordinating the Volume •Data has always been a challenge •Always been Fragmented, Incomplete, dated •Limited by tools and Computing power Demand Meeting Supply Meeting Gather Data S&OP Meeting Pre S&OP MeetingS&OP stands for sales and operation plan and sales and operations planning at the same time It is both a plan and the process that creates, implements, monitors, and continuously improves the plan The S&OP process involves a series of meetings to meet a consensus A demand and production plans that reflect the results of demandside sensing

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

What Is S Op How S Op Works Demand Planning Com

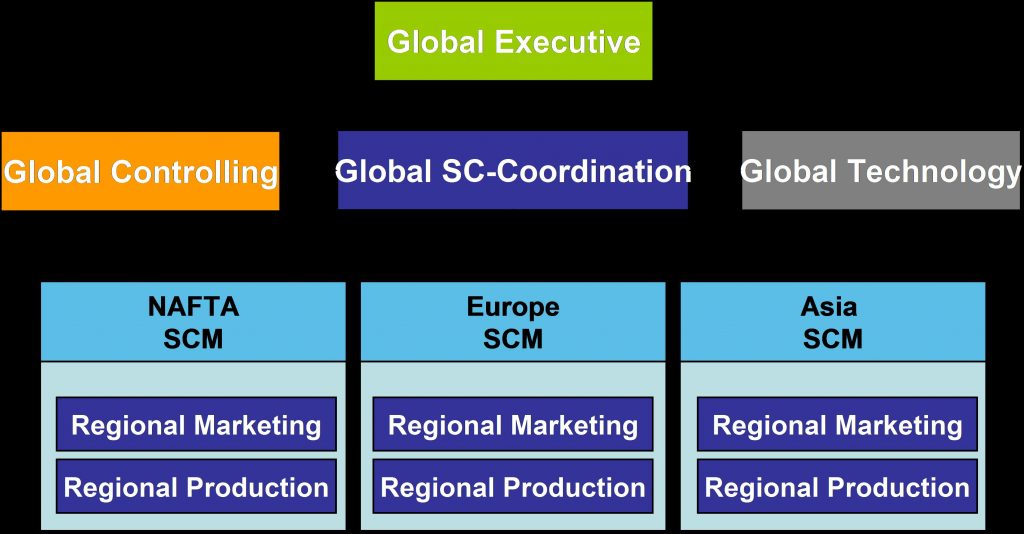

S&OP is much more than just a meeting – it takes into account all the various planning and monitoring processes that are necessary to run a worldclass supply chain The challenge for businesses lies in capturing and summarizing the data required to support the process, and the ability to turn that data into informationDemand Planning Translate demand in net requirements Supply Planning Review production capacity and ability Pre S&OP meeting Resolve issues, recommendations and alternative plans Executive S&OP meeting Single companywide plan Page 7 What is S&OP Organizational position Marketing ManagementDemand Planning is an Integral Part of S&OP S&OP is a collaborative process to arrive at a balanced demand and supply plan Using collaboration to arrive at Demand Planning provides a better signal to the S&OP/IBP process S&OP Strategic Plan Master Schedule Demand Plan Production and Material Plan Three to five year strategic plan for the family

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

2

The (S&OP) process consists of a lot of leg work to support the three main meetings Pre S&OP Demand, Pre S&OP Supply, and the S&OP meeting itself (OK, some companies have a fourth one The Executive S&OP meeting) The whole process is designed to allow a company to make the best possible plan for the future based on current estimates, asWhat is Sales and Operations Planning (S&OP) and why do you need it?At a recent seminar Steven Thacker explained 👇 TIMESTAMPS (in case you want to skip) 👇 Sales and Operations Planning (S&OP) A integrated business process that drives collaboration, focus and alignment across multiple divisions and departments in a company 5 • Demand plans • Financial goals • Supply plans • Inventory quantities • New product plans S&OP brings together Inventory 6

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Forecasting Process Sales And Operation Planning Ppt Download

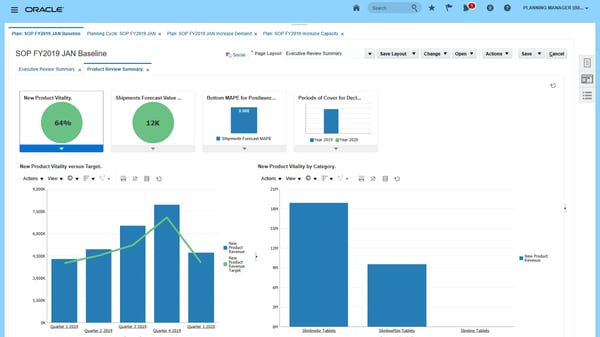

Seven S&OP Reports Every Manufacturing Executive Needs 7 2 S&OP Executive Review Dashboard This dashboard facilitates the S&OP executive review process The consensus or preS&OP meeting provides the details to the executive review process, and this dashboard provides visibility into the status of those submitted operations and supply chain plans Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational Sales and Operations Planning Process Guide STEP 4 S&OP Integration & ReconciliationPURPOSE INPUTS OUTPUTS•Resolve availability constraints •Reference to Product Portfolio •COLLABORATIVELY•Ensure plans aligned with strategy / Review • Constraints minimizedbusiness plans •Issues from Demand Reviews • Fulfillment plans aligned

What Is One Plan S Op Arkieva

S Op Made Practical The European Business Review

4 PreS&OP meeting During this stage of the S&OP process, leaders from finance, sales, marketing, operations, materials, product management, and human resources meet to collaborate They'll compare the forecasts to the demand and supply plans, and they'll consider the financial impact of the plans Sales & Operation Planning (S&OP) is a process to align an organization across all functions, so that operational capacity is optimized, balancing demand (sales) and capacity When done well, S&OP allows business to capture efficiencies in their operations and sales from the market because they can proactively adjust their business as forecastsAll are pulled together in the segment S&OP meeting

2

Supply Review Meetings

Meetings are held before the official sales and operations planning meeting to resolve any demand and supply imbalances with alternative supply chain options Case Study – Manufacturing Company S&OP Process A consumer goods company markets its electronics products in North America Since its product offering has less known in the market thanS&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is toSales and Operations Planning (S&OP) is an offshoot of production planning and owes its evolution to practitioners of operations management It is looked at as an extension of aggregate planning

You Simply Need To Know What Do Next

1

Orchestrate all players with sales and operations planning (S&OP) while remaining aligned with your business strategy and financial objectives We have the time and insights to focus on scenario management and decisionmaking documents for the S&OP meeting" from the customer demand, the whole planning and the feedback to the The S&OP process focuses on the tactical horizon, typically from 3 to 18 or 24 months When developing the process timing, the key point in the calendar is the existing business planning meeting This has to become the executive S&OP meeting, and the process steps leading to that have to be backward scheduled accordinglyPlanning volume mix demand supply Thus SIOP is a monthly formal balancing of supply and demand through a six to twelve month planning horizon by aggregate product families It generally includes incoming orders (bookings), backlog, shipments, forecast, finished goods inventory production and capacity

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Sales And Operations Planning Relex Solutions

Demand Planning is just one of five steps of the whole S&OP process The Demand Planning step uses the statistic sales forecast and the experience of other areas in order to estimate future demand

1

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

Sales And Operations Planning Report Do You Get Surprises

Implement The S Op Process For Supply Chain Success Learn About Logistics

Best Of The Best S Op Conference Ppt Video Online Download

Scm Awareness S Op Process Planpotential

1

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

Sales And Operations Planning S Op Logistiikan Maailma

How S Op Improves Your Organization Tmc Fr

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Sales Operations Planning Scpi

Pdf Sales And Operations Planning Part I The Process Semantic Scholar

Pdf Executive S Op Managing To Achieve Consensus

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

S Op And S Oe A Symbiotic Relationship

Sales Operations Planning Engagement Model Tvo Maine Pointe

How Does Sap Ibp Help Supply Chain Manager Align Demand Supply Plan To Annual Operating Plan Krypt Inc

5 Suggestions To Improve Pre S Op Demand Planning

Tackling Life S Big Questions What Is S Op

What Is S Op How S Op Works Demand Planning Com

How Can Demand Management Drive Your Sales Operations Planning Moore

What Is S Op How S Op Works Demand Planning Com

Supply Chain Graphic Of The Week The S Op Process

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales And Operations Planning Business Forecasting Taruna Nagpal

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning 4 Fundamental Concepts Sourcecodematrix

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

Future Directions For Planning Supply Chains Using S Op Learn About Logistics

What Is S Op How S Op Works Demand Planning Com

Scm Portal Insight The Five Steps Of S Op Process

1

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

How To Make The S Op Process More Robust Demand Planning

2

What Is S Op Sales And Operations Planning Explained Anaplan

Competitive Advantage S Op Whitepaper Insights Publications Resources Gra

Mindmap For S Op And Ibp Supply Chain Movement

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

Demand Planning Vs Supply Planning Balance Is The Key To Success Plex Demandcaster

S Op Process Template

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

A Comprehensive Overview Of Sales And Operations Planning S Op

Ultimate Guide To Sales And Operations Planning S Op In 21

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

How To Get Your S Op Process Right Sku Science

Sales And Operations Planning Myths Part 2 Supply Chain 24 7

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

S Op Implementation Roadmap

My S Op Process In Jan Executive Summary In Place S Op Meetings Correct Sequence Of Meetings Demand Supply Pre S Op And S Op Meetings Ppt Download

Executive S Op And Demand Forecasting Workshop Nexview Consulting S Op Consulting

What Is S Op How S Op Works Demand Planning Com

Oracle Demantra Sales And Operations Planning User Guide

2

Who Should Own Sales And Operations Planning I Kinaxis

Sales And Operations Planning

Sales Operations Planning Consulting Supply Velocity

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

What Is One Plan S Op Arkieva

A Comprehensive Overview Of Sales And Operations Planning S Op

Demand Planning Defined

What Are The Basic Elements Of The S Op Process Quora

Apics Principles Of Sales Operation Planning S Op Knowerx Top Level Partners Of Apics

Sales And Operations Planning Process Customer Data Gather Powerpoint Slide Templates Download Ppt Background Template Presentation Slides Images

S Op Process

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

Reporting Forecast Accuracy At Sales And Operations Planning Meetings Supply Chain Link Blog Arkieva

S Op Sales And Operations Planning Demand And Forecast By Achain Management Issuu

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Information Sharing For Sales And Operations Planning Contextualized Solutions And Mechanisms Sciencedirect

Sales And Operations Planning Explorescm

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Pdf Sales And Operations Planning S Op An Overview

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

Sales And Operations Planning A Project Manager S Guide Asana

A Comprehensive Overview Of Sales And Operations Planning S Op

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

2

0 件のコメント:

コメントを投稿